Solutions

Innovative systems for

seized fastener removal

Powered by electro-discharge machining (EDM) technology

We have adapted electrical discharge machining into two systems, FastEDR and ARTES.

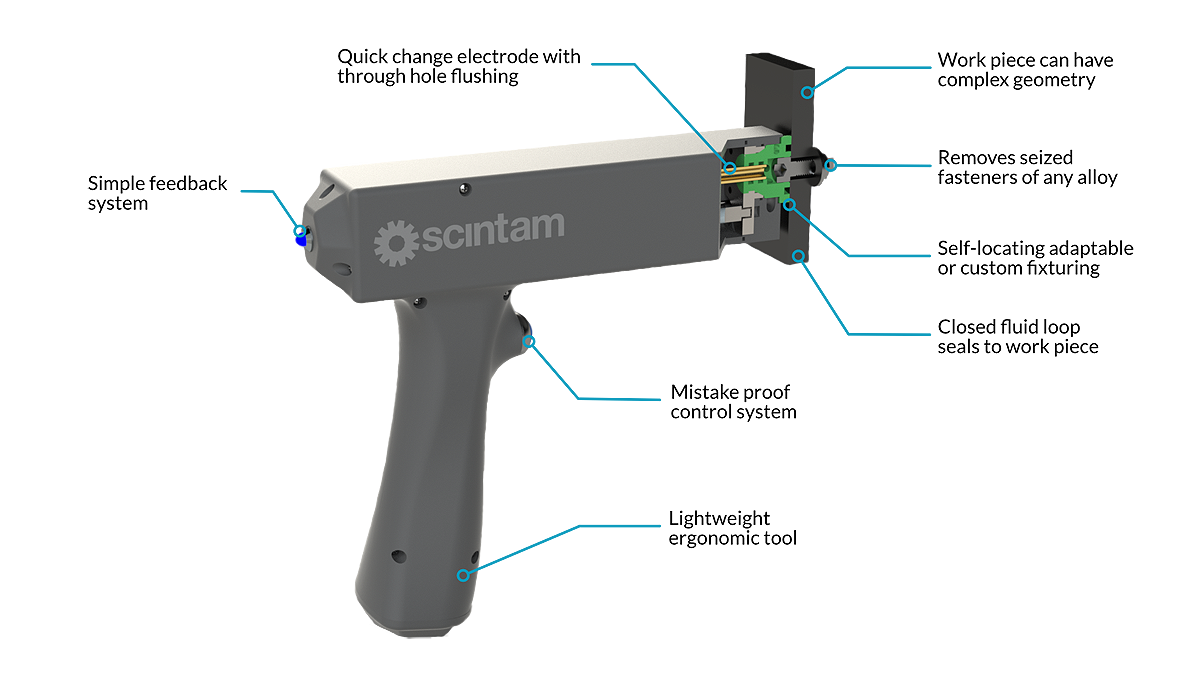

FastEDR makes fastener removal safe, predictable and repeatable. It eliminates the risk of damage to high-value assets and enables the removal of fasteners in the same amount of time, every time. This makes aerospace maintenance processes more efficient.

Our system comprises a portable base unit and a tool head. The base unit has an intuitive interface and intelligent software to ensure fasteners are always eroded correctly. A range of custom-designed tool heads locate, erode and remove any seized fasteners from any alloy.

The FastEDR process itself uses electrical pulses to dissolve metallic fasteners on a microscopic scale. This method uses no chemicals or mechanical force because the electrode never comes into contact with the fastener.

An enclosed volume around the fastener means the process is fully isolated from the operator, and both the fastener and the workpiece always remain cool to the touch. This ensures no heat-affected zone or changes in microstructure are generated in the component from which the fastener is being removed.

ARTES stands for Automated Remanufacturing Towards Environmental Sustainability and has applications in the automotive and rail industries. Our ARTES CNC machine is designed for remanufacturing at scale, using a high-speed, repeatable process that needs minimal operator intervention. It means potential scrap can be refurbished into valuable components.

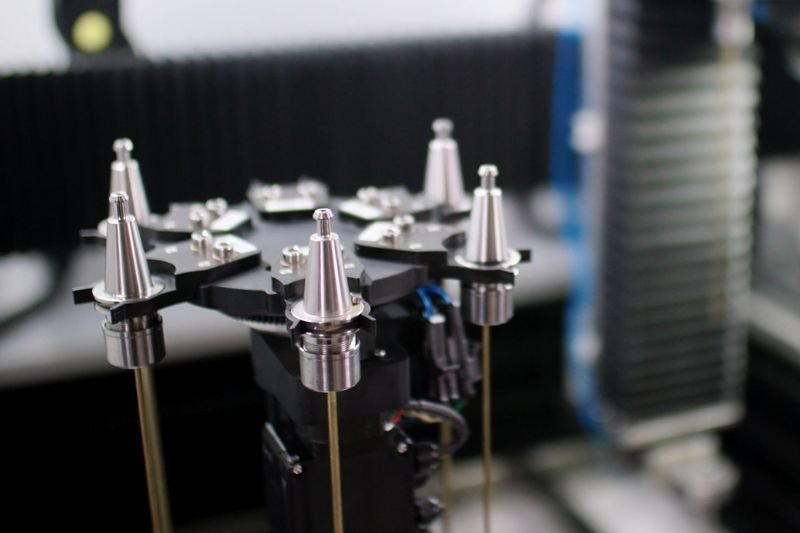

The EDM system overcomes one of the biggest barriers in remanufacturing: disassembly. It integrates CNC servo axes with a purpose‑built frame and streamlines the process of removing fasteners.

Electrical pulses remove seized fasteners quickly from even the hardest alloys, and automation ensures high throughput of parts. ARTES enables unattended disassembly of components, and no CNC experience is required.

The custom fixturing system enables multiple parts to be processed in batches. ARTES brings worn or damaged components back to an as-new state, faster, safer and cost-effectively.

OUR PRODUCTS

FastEDR

The core of FastEDR is our portable power unit, which contains all of the equipment required for the EDM process and to control the operation of the tool head. Once the fastener type is selected, the operating parameters are automatically loaded for quick and easy operation.

The system can be configured with different tool heads for specific fasteners and components, which can be changed over in under one minute. It has a range of power supply inputs (worldwide single or three phase, aircraft power [400Hz]).

The versatile tool head can remove a wide range of standard fastener types with minimal setup time, and Scintam has a library of fixtures for different specific component geometries. FastEDR enables the user to switch from removing nuts and bolts to removing rivets, screws and taps in seconds with our simple electrode switching method.

ARTES

ARTES is a large-format EDM machine that simplifies remanufacturing through automation. It removes seized fasteners through an accurate and repeatable process, and transforms scrap metal into reusable parts.

It is a static, fully enclosed EDM system with multiple CNC-controlled servo axes. The expansive work area maximises productivity, and it has long travel for large parts. The operator-friendly design includes an industrial camera for machine vision and a flexible machine layout to suit your workspace.

It has six tools for extended operating time, and custom fixturing is provided for each specific application. Tailored for speed, it processes multiple parts per hour and can remove fasteners from any alloy.